The GreensandPlus Filter

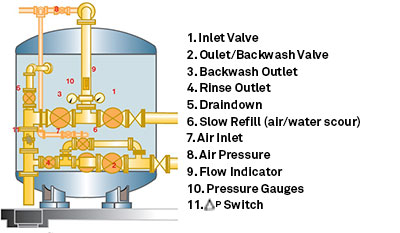

H&T developed and patented the continuous regeneration process for iron and manganese removal in 1963. This process used a feed of chlorine and potassium permanganate upstream of a manganese greensand filter to keep the catalytic manganese dioxide coating of the manganese greensand media regenerated. Our method became the industry standard for the next 40 years. In 2005, H&T introduced GreensandPlus, the next generation in manganese dioxide–coated catalytic filter media. GreensandPlus has all the same physical properties of manganese greensand, so it can be used interchangeably, but GreensandPlus has many operational advantages over the old media. First and foremost, it does not need potassium permanganate for regeneration. It can be regenerated using only chlorine or any strong oxidant. It is also much more durable, withstanding differential pressure up to, and above 20 psi. (Manganese greensand crushes into fines at differentials higher than 12 psi.). It has higher capacity, resulting in less frequent backwashes and a lower percentage of waste, and can operate at higher flux rates than the older product. H&T has many water-treatment installations operating at 8 gpm/ft2 and some as high as 12 gpm/ft2. If necessary, we can incorporate an air/water wash system that simultaneously uses air and water to backwash the media when treating water with elevated levels of manganese.One of our many underdrain designs uses a 5-inch square stainless steel expansive port distributor. The slot opening is controlled by a movable spline that prevents plugging and offers many advantages over a strainer with a fixed-slot opening, which is irreversible once it becomes plugged. The H&T iron and manganese filter system has been refined and modernized over the 50 years we have designed and built this type of equipment. It remains the most reliable system that can meet the most demanding requirements and widest variety of applications on the market today.